The Thundersley/AC INVACAR

In 1948 the English motorcycle enthusiast Bert Greeves adapted a motorbike with the help of Derry Preston-Cobb as transport for his paralysed cousin and Invacar Ltd. was born. It's the AC and Thundersley Invacars which are the most famous versions of the 3-wheeled invalid carriages but as the Virtualgaz team explains, the first invalid carriages resembled nothing more than three-wheeled tubs.*

In the early 1920's, Stanley Engineering of Surrey manufactured the bulk of the UK's self-propelled invalid carriages using the 'Argson' brand name. The introduction of the petrol engine was a natural progression as was electric battery power and by 1949, Stanley and other manufacturers like Harding Ltd. and Dingwall & Son had lucrative Ministry of Health contracts.

The first motorised tricycle was powered by a fan-cooled Villiers engine in 1922 while the first ever fully enclosed 198cc version was developed during 1938.

In 1948 Dingwall brought about the flat twin Coventry Climax air-cooled and chain driven go-cart styled carriage as Invacar, Barrett, Tippen & Son, AC Cars Ltd. and George Fitt Motors all gained M.O.H. contracts using mainly the Villiers 147cc power unit.

After some dubious 2-seated versions in the 50's, the M.O.H. standardised its requirements - 147cc Villiers, single seating and steel pressed wheels. Single front wheel drive, hydraulic braking and electric Dyna starting soon arrived.

A 1951 fawn and sage 'Padwin' prototype and the 1949 AC luxury version.

The Harding 'Spinal Carriage' of 1932 and the fibreglass Harper 'Model 55' of 1955.

Mid 50's Invacar 8a Model 52 and the 'Vi-Car' painted pinky-grey and a Barrett Minor.

During the 1960's and 70's the Invacar ruled with its modern fibreglass shell, ice blue colouring and belt drive, which might intrigue you if there is a Parts Geek or two out there reading this. Extended wheelbase, a wider track and use of Austin Mini wheels saw the Invacars right through to the end of the final DHSS contract in 1977.

5,928 Invacar Model 67 'Acedes' carriages were built.

A 1966 'Delta' by Frank Tippen Ltd. and the aluminium Invacar Model 57 which was available only in blue with a petrol engine (13,155 manufactured) or the rarer 72-volt electric version - both with sliding windows.

1957 Harper Mk VI with rubber suspension and a 60's Mk12 Invacar with a white roof.

A 1968 prototype Model 70 with the Fiat 500cc parallel twin and 'Denny' Denly MBE, founder of the Invalid Tricycle Association who, on his 1946 Argson Deluxe, crossed the Alps in 1947.

...

... ...

...

| New Thundersley Invacar rolling off the Essex production line... | 1976 respray | 1974 'Poo' |

Original Model 70 Brochure. Thanks to Dan Vitaletti Arvada, Colorado, USA.

Dan Vitaletti: "Hi, Invacar Instruction Manual which I recently bought on E-Bay. It is for the Greeves Invacar Mark 12E Invalid Car (1969-70). Though it primarily provides operating instructions, there is info on maintenance and repairs, including a wiring diagram. I can provide copies if anyone is interested. Thanks Dan Vitaletti, proud owner of the "Only Legally Owned Invacar in the World" Arvada, Colorado".

.....

.....

.............

.............

..........................

..........................

FOR SALE

1976 Invacar

Handlebar version finished in 'Ice Blue'

58,000 genuine miles, recent full respray and recon. 600cc engine

First to see will buy - but it was never allowed !

![]() Robin

Kettle's take on the Invacar (Apr 2010):"Would you consider

placing a link to this article of mine entitled 'A disabled person's view

of the Acedes Invalid Car' using this link:

http://ableize.blogspot.com/2010/04/anybody-out-there-remember-dreaded.html

Robin

Kettle's take on the Invacar (Apr 2010):"Would you consider

placing a link to this article of mine entitled 'A disabled person's view

of the Acedes Invalid Car' using this link:

http://ableize.blogspot.com/2010/04/anybody-out-there-remember-dreaded.html

![]() Peter

Wonnacott (Dec 2009):Here's Peter's full account of his time spent

working at Thundersley... it's abit of a read but PRICELESS STUFF!

Peter

Wonnacott (Dec 2009):Here's Peter's full account of his time spent

working at Thundersley... it's abit of a read but PRICELESS STUFF!

"Having tried a variety of professions throughout my working life I could be termed as a jack of many trades but a master of none, and few of them can I say have given me any sort of real job satisfaction where I could feel confident enough to claim that at the end of one working day I felt sufficiently fulfilled enough to actually look forward to going back the next day to begin all over again. But, out of a total of some twenty plus different employments that I tried one in particular meets the contentment factor hands down, and that one is the very first job I secured when i moved down here to Canvey Island in Essex.

Having brought my family down here lock stock & barrel we all moved back in with my parents in their large bungalow at 6 Berkeley Lane for a few months whilst I established myself with a job, this feat I accomplished within the first week of moving down as jobs back then were by and large easier to obtain particularly if you were not too far distant from the many industrial estates that littered the area which were growing in size annually. Noting in one of the local papers a job offered on the Manor Trading Estate At Thundersley In Benfleet just a few short miles from where I was residing it was for a motorcycle engine builder at the then young flourishing company of Greeves Motorcycles which also incorporated Invacar a major subsidiary owned by the same company housed within its factory which at the time comprised of a number of separate units spread around all within a few hundred yards from the main factory building and constructed motorised invalid carriages under contract for the government. Having been engaged for the advertised post I settled in working alongside (at the time) three other fellows who, amongst them was an overall working charge hand who did the same manual work as the rest of us and made sure things ran smoothly. For us as a small engine assembling work group nothing was written down as guidance regarding settings, measurements etc, etc, and these had to be learned by us all as we went along, me, having the worlds worst memory of anyone worried myself to death having been shown just once how to assemble a complete unit was shown to my section of the long workbench to struggle on and begin building engines without assistance from the others although any questions or queries were usually answered by them as you muddled along desperately trying to copy the fellow alongside as he built up his own unit.

In the beginning I thought it was an almost impossible task for me to master and often spent many a sleepless night worrying I would never get to grips with all the different components and order which they went in to build a complete unit from scratch ready to be fitted into the motorcycle frames by another team of chaps situated in a far corner of the factory after they had been individually tested one by one by two testers who had to first fit them into a test frame they each had and physically drive them round a test route on the main road. My fears of not mastering this complex assembly procedure was unfounded as within the space of 9 months or so, I was building the damn things in my head with ease and instead of counting sheep as the saying goes I was assembling them within my head and sending myself to sleep. Unbelievably after some two and a half years or so of doing this regularly on a daily basis the job became to tedious for my liking and I promptly left to join a smaller engineering company located on Canvey itself manufacturing component parts for marine use. Conditions were poor at this small family run concern and all the equipment was outdated by many years and what with one thing and another I began to regret leaving my previous job at the Greeves factory and phoned the fellow again as before that had originally engaged me at the offset, only to be told that my old position was no longer available as another fellow who worked at the company had filled the position after I left. He did however offer me a post working at the company but for the other subsidiary invacar working in the test and rectification department.

From the time I originally joined the company as a whole the management team running the plant consisted of Oscar (Bert) Greeves, Derry Preston Cobb, P.A.Cobb, John L Ralling, & Roy Halls all directors fulfilling various roles overall, (not sure how many of them were financially involved shares wise). Bert Greeves had by this time taken a back seat as regards to dealing with the day to day running of the company and chosen to retire spending the greater part of his time abroad but still having a major controlling interest in the decision making of certain things in the plant. John L Ralling was the main engineering design genius behind many of the up and coming ideas that went into much development regarding the motorcycle side, and Roy Halls was overall manager dealing with the workforce as a whole mainly doing the hiring and firing (which the latter was few and far between). Roy preferred to keep things in the family and at one time his father William (Bill) Halls worked there in the manufactured parts inspection department and in more recent years as Roy’s son Robert came of age he too was given employment working in the maintenance section,(not sure who joined the company first Roy or his father) but during my time there Bill retired. Roy’s right hand man who shared his office was a very, very, pleasant fellow by the name of Eric Kuruber who not only had a positive attitude but also an easy going approach to most things, most important decisions he had to first run by Roy to gain approval and one day I said to him, Eric why do you not make these decisions yourself instead to which he replied. There is one little word in my job title that prevents me from doing so, and that is the little word TO, my correct titling position is Assistant TO the works manager and that makes a world of difference regarding decision making, I never gave such a thing a second thought before but when he pointed that fact out, he was exactly correct.

The entire workforce was treated as one big happy family and aside from one or two foremen and charge hand’s littered around the various departments most employees were left to their own devices as long as the work flowed without problems which of course it did, aside from one or two staff members that in those days abused the system (as happens even now throughout industry) after five years service at the company you automatically were bestowed to staff status which meant you never had to clock in or out but were put on trust to adhere to the rules you followed when you did. I often was told stories by various long serving folk who worked there including one Ben Nash who eventually became the Invacar production line foreman, of times during the fifties when the industrial estate was in its infancy, and the company was a lot smaller but growing in the early stages, when comradery was much more rife especially amongst the section that dealt with the Greeves motorcycle side. Fun was abound in those days apparently with many of them after a days work would be allowed to each take a motorcycle to a section yet undeveloped at the top of the estate and all have a good thrash around creating a cycle course of their own doing and often this included Bert Greeves himself being much younger way back then, these times gradually diminished as time progressed until finally ceasing completely.

[OSCAR (Bert) GREEVES HAD A PERSONAL FLAT BUILT JUST A FEW HUNDRED YARDS FROM THE MAIN FACTORY BUILDING. BEHIND HIS UNITS WAS THE ALUMINIUM FOUNDRY - ALSO OWNED BY HIS COMPANY WHICH SUPPLIED ALL CASTINGS REQUIRED, WHETHER FOR MOTORCYCLE OR INVACAR PRODUCTION]

As was the norm at that particular company, (and maybe others possibly), when ever an existing charge hand retired or left employment there the next longest serving member or suitably experienced person automatically got offered the post as I did and accepted. The job as a whole kept me interested throughout as I virtually had carte blanche to do whatever I pleased (within reason of course) and as a direct result made the job much more enjoyable for many of us, as long as the cars kept to plan day by day meant I could road test any vehicle that required doing so, or solve any rectification problems that manifested themselves regularly on the vehicles, either personally fixing them myself, or guiding the team under me should they in turn not be able to fix a particular problem themselves.

This position I held was taken seriously by me, but also had a fun side to it the more you worked on these cars often nicknamed by many of us as spaz wagons affectionately, a phrase frowned upon often by Eric Kuruber. The wages were nothing spectacular there but the few exceptions were to be found by the minority of small engineering component production crews that worked on the shop floor under a piece work basis, it was said that certain fellows could often earn excessive wages by working so hard as to treble and sometime quadruple the rates set down for the jobs that they were doing. Each time the management lowered the rates to avoid this they simply went faster still until it reached a stage whereby it was impossible to reach such targets by these few men and things settled down, to a more sensible pace. Although by and large a certain section of the workforce relied heavily on the 10 hours overtime that was regularly available to subsidise the poor take home pay and extract a living wage, it was on rare occasions cut considerably for short periods when finances got tight for the company through one thing or another.

I always tried to treat the chaps I worked alongside with fairness when this thing cropped up and when requested by the management to restrict all overtime to a maximum of 10 hours in total per week for the section unlike many others that would through their authorative position could and did often take it all for themselves, as much as money was in short supply at home I have never let money be my god throughout my entire work career and would share it around at 2 hours per person per night so we each got a bite of the remaining cherry so to speak, this act also kept the team satisfied and contented and ensured to get the best out of all concerned during the working week.

The main model when I rejoined the firm, was a rather narrow re-enforced glass fibre body mounted upon a steel three wheeled chassis and powered by a single cylinder air cooled 197cc Villiers two stroke motorcycle engine unit that drove the near side wheel via a chain and sprocket, and engine speed controlled via a twist grip throttle on the end of the tiller bar (much the same as on a motorcycle), quite surprisingly despite drive being applied only to one rear wheel amazing traction was gained even in snow and ice conditions. Gearing was by a four speed motorcycle gearbox all in one unit as would be found in use on many a small motorcycle of varying manufacture of the day, heating was supplied via a heat exchanger unit that drew heat from the exhaust and suitably piping it into the drivers cab, and an engine self start was in the form of a 12 volt Siba Dynastart all contained within the engine unit construction which upon starting the engine automatically became a dynamo charging unit with an output of some 90 watts capacity supplying power to keep the battery charged as well as all the lighting as in a conventional motor car. Behind the driver situated on a shelf at shoulder height was a control unit that served not only as a voltage regulator but also incorporated a system operated by a small lever by the driver on the control console enabling the engine to be started anti clock wise thereby giving a reversing factor theoretically allowing as fast a speed to be obtained in reverse as in forward but as I recall there was some sort of limiter incorporated within the system to prevent such a situation thereby governing such an act in anything but the bottom gear that was selected manually by the driver. Standard control was by a single tiller arm which was usually mounted on the right hand side and extended across the front of the driver which also contained the clutch and brake assembly and served to steer the single front wheel and entry/exit was via a sliding door on the nearside of the vehicle which slid towards the rear of the vehicle when opened.. There were a number of variations in place to cater for different stages of disabilities ranging from the bizarre to in my opinion the downright dangerous in the wrong operators hands but it must be remembered these vehicles were only intended to give a bit of freedom to disabled folk who would otherwise be forever restricted to relying on others to escort them around giving them no personal independence otherwise as there were few alternatives in place for many years on a production basis other than specially adapted conventional cars which took an age to convert due to the controls having to be designed and built to suit any and every make and model that was needed to be adapted at the time.

During the early 70s a new model was designed (not sure by who exactly) and put into production but the development I believe, was possibly undertaken by the AC Car Company of Thames Ditton In Surrey (of The AC Cobra Fame) and dubbed the Model 70. Still on a steel chassis containing a fibreglass body it was a much more modern unit with a low wide wheelbase still with the three wheel configuration but with a forward sliding door situated on each side. Standard steering was by a central tiller bar containing a handlebar configuration which also doubled for the braking system when pushed in a downward motion. Power unit was supplied by a 500cc Steyr-Puch horizontally opposed flat twin cylinder air cooled configuration with a separate starting motor linked to the crankshaft via twin vee belts that like its predecessor became the charging unit once the engine was running freely, in effect termed as a dynamotor. The transmission was a design based loosely on the tried and tested on incorporated on the Daf 44 and 55 small family saloon cars but where they had an independent drive belt each side to drive the rear wheels these were designed to operate using a single drive belt situated between two sprung loaded pulleys that automatically adjusted themselves according to the speed of the road wheels constantly. Using this type of Variomatic drive system meant that at all times the pulley ratios were always at their correct position for maximum torque and speed to the driving wheels as well as being not only the replacement of a conventional clutch unit but also becoming a drive system that replaced a conventional gearbox unit. This particular transmission build was unique only to these model invacar and from our point of view appeared a fairly reliable unit giving only one or two problems occasionally with the Salisbury pulley drive system, the downside of these constructions were they emitted a distinct high pitched whine when in motion. Likewise with the engine units, we had very few problems with them on the whole but if any fault was found being brand new we simply replaced the whole units rather than play around trying to rectify faulty components, we never found the need to stock a supply of spare parts, anything on this scale would have been done presumably by the various repairers spread about the country. This assembly was situated at right angles to the engine unit and sat immediately behind the driver shielded of course by a removable panel behind the driver seat to facilitate any maintenance procedures that may be required throughout the motors lifetime. Both rear wheels were driven via a differential unit within the transmission assembly and a gear selector situated in the centre of the dash panel allowed the driver to select forward or reverse with neutral being in the centre of the two, this model however really could travel as fast in reverse as in the forward gears by default if the driver had the skill and courage to attempt such a feat, a foolish and dangerous thing to try under normal circumstances by anyone other than a driver who had the necessary skills to try this on or off any public road. Heating was again done via the engine from the hot air circulating around the engine being piped into the drivers cab via suitable heat resistant hoses. Comfort within the cab was initially very sparse but later some engine noise sound deadening insulation was added as was a headlining to increase the appearance aesthetically more than anything.

Controversy began to rage amongst the disabled fraternity throughout the country claiming these little blue vehicles were too distinctive, restrictive to many of their needs and requirements and in the same light stuck out as a result in the traffic like a sore thumb bringing unwanted attention to the fact that the drivers were in fact different from any other road user of the day. Celebrities were used in this public campaign which included the likes of the well known Racing Car Drivers of the day Sterling Moss and Graham Hill especially if my memory serves me well (which it seldom does, LOL!!) I think it was Sterling, following some sort of accident was offered the use of one of these vehicles while he recuperated and quickly condemned them as being unsafe, impracticable or some such other reasons that added fuel to the fire in favour of all the public outcry at the time. Personally as an able bodied driver I found these vehicles easy to drive, park, operate and safe under normal conditions, however, in a high wind on the open road even at a severely reduced speed they were so front end light (we would frequently single handed, lift the front of a vehicle shoulder high to turn it at right angles in a tight situation at the factory) that each gust of wind was like a huge hand trying to force the front of the vehicle either off the road or into the path of oncoming vehicles and unless you were ready and able to take suitable corrective actions to combat this phenomenon I would imagine it could not only be very frightening and un nerving but also dangerous and worrying to any person other than an experienced tester such as myself.

Ultimately the government responded and the decision was taken to scrap these purpose built vehicles and offer various packages to different disabled folk whereby they could be allowed to select any ordinary motor of their choice and get them adapted with suitable controls as an alternative safer replacement vehicle that was less conspicuous was either found or manufactured in the near future. This has been achieved in the form of the Canta a Netherlands a purpose built mini car whose power plant is by a single cylinder 340cc Honda engine with a top speed of 45mph and constructed basically of ABS plastic. During my employment at the factory I saw many changes take place to the main building which was extended prior to the new style Invacar introduction during the early 70s and a new production line was incorporated within the main factory having been moved from a building being used across the road to build the previous models.

The demise of the troubled company began when Bert Greeves finally decided to retire completely withdrawing his shares from the firm which presumably the lions share was, so to speak, leaving the remaining shareholders floundering. A couple of fires erupted at different times causing damage, one being discovered one Saturday morning during working hours took place in an upstairs storeroom that contained various filing cabinets and paperwork, this was fought by myself and one or two others using extinguishers but the fire had got too good a hold and blew part of the asbestos roofing off in the heat before the fire brigade arrived to quench the flames. Those of us involved were thanked by the directors personally and received a small financial reward as a mark of their appreciation for our involvement in fighting the fire, which had we left it and waited solely for the fire brigade to arrive, could have been a lot more damaging than it turned out to be finally, it was concluded that rodents chewed through a power cable in the room causing bare wiring that eventually sparked setting fire to paperwork in the room. A short while after re-joining the company and working on the Invacars I requested and got permission to use a car to and from home during a road test and continued this practice throughout the remainder of my employment there, I must have been one of a few privileged folk in the country to always arrive to and from work in a different brand new vehicle each and every working day, numerous times the police stopped many of the testers either whilst testing these cars or the motorcycle testers and tried to find reasons as to why we were flouting the law by misuse of trade plate usage but due to their doubts as to these actual laws governing this rule, they seldom followed any enquiries up and we invariably heard no more, so continued with these practises throughout. After Bert retired and left the company in disarray financial wise, a replacement shareholder needed to be found to re-inject sufficient finances back into the company to ensure survival and this came in the shape of a fellow named Gilroy, not sure if he bought the company outright or if he simply became the major shareholder, but he appeared to take the reins and appeared to be the driving force and the main controller. He made many alterations and cutbacks to rescue the failing company profits and amongst these were the abolishment of the daily restaurant bills accrued by all the directors for many a year as they dined locally each and every day all at the company’s expense. A decision i don’t think many of them favoured but little or no protest was lodged when they found out their gravy train had ground to a halt for all time. I cannot recall if just prior or after Gilroy joined the company a second and more devastating fire destroyed a major part of the main factory building and offices, it was discovered the fire originated within the main stores due to a faulty heater being accidentally left on after everyone went home for the weekend one Saturday afternoon , I personally have my own doubts about both these fires but as both times no foul play was suspected or found maybe my suspicions are somewhat unfounded on this matter.

Arriving for work on the Monday morning my jaw dropped upon seeing part of the roof had collapsed as well as all the obvious flame and smoke damage apparent indicating what had occurred over that weekend since I left to go home on the Saturday. This only added to the continuing troubles that befell the company over the years and upon receiving an insurance payout that saw a new office block and repair work rejuvenate the building, no doubt the amount the company was insured for fell short of the total losses incurred as a direct result of this fire damage and one that merely added toward the struggle to survive. The death knell was finally dealt as by now all the Greeves motorcycle side was doing was wasting any profits accrued by the invacar side as the Japanese continued to dominate the market with their superior machines that they were introducing throughout the world. To top it all finally the government announced its closure of all orders for any further invalid carriages from all manufacturers that had been the main source of bread and butter regarding a steady income to enable smaller engineering works such as ours was to continue to survive. AC Cars At Thames Ditton were the constructors and suppliers of the transmission units to us throughout the life of these cars being built as well as their own production of the same cars with the only defining difference being the front badge as far as I am aware, and upon the cancellation of all orders to produce further new vehicles one would assume that for the best part employees were made redundant with only a skeleton staff remaining to produce a few transmission spares needed for a few years more in case they were needed to continue to keep existing motors running as long as possible but this is only guesswork on my part. Unlike the Thundersley factory AC Cars main production output had always relied on sports and high powered cars being produced by their company to be their main source of income so I would assume they simply fell back on these as their main source of income to enable them to continue as a manufacturer in their own right as an established company ensuring their survival for more years into the future.

Back in those days many lower paid manual workers were often paid as we were by a weekly wage packet with all deductions done for us by default from the wages department, this company consisted of some two hundred or so employees in all or thereabouts and many of us were treated on an individual basis regarding the hourly rate of pay each of us received. Aside from the original standard agreed hourly rate upon joining the company there was a scheme in place at the time which rewarded individuals who at some time or another had been asked to help out in varying other departments on occasions and for this reason were suitably rewarded by an increase in hourly pay by a few pence accordingly depending upon how many other departments they had been asked to work in, this was termed as ability money. Over the course of time this began to cause problems particularly with new employees joining the company at different times, who began complaining that they too were equally capable of working in multiple departments but were never given the opportunity to prove their worth so deemed this practice as unfair, and eventually to avoid any further conflict the directors decided to abolish this method altogether and simply give a person an increase purely on their merit within their particular department, even so with many production workers working to a piece work schedule the total wage structure must have been a nightmare for the wages department as a whole often resulting in regular mistakes being made with promises to correct them the following week to avoid holding vast amounts of petty cash on the premises other than the set pay days. During these periods of assisting in other department over time I got to work in the maintenance, sheet metal, parts production and tool room departments all of which stood me in good stead for future employment at other companies through the extra experiences gained as a direct result.

Whilst working in the Test & Rectification Department over the years there it was inevitable I guess being out on the road so many times each day in different vehicles that incidents would occasionally occur, most, fortunately, were amusing rather than serious. Two such happenings occurred at different times I recall of which I shall attempt to describe now. The first was on an outward bound car road test which took me up the steep hill by the church not a quarter of a mile from the factory on the way to the set route we always travelled to put a small mileage on the brand new speedometer mileometer. As I went over the brow of the hill I accelerated the few hundred yards up toward the junction at hart road beginning to slow in anticipation at the junction corner as I had done hundreds of times over the course of my testing career with these vehicles, a few dozen yards before the junction to the right was the village post office and as I approached I observed a lady waiting in anticipation in her car by the post office to pull out and continue her journey the same way I was travelling. Keeping my eye on her I observed she was looking straight at me so thought she had seen me and would wait until the road was clear before she finally pulled out, when I was all but on top of her she decided to pull across the road in front of me at the last minute giving me not a cat in hells chance of ever stopping in that short a distance and with my tyres screeching and brakes fully applied I slid into the front nearside of her car at the same time turning the handlebars on full left lock and ending up on the pavement. Stopping immediately she leapt out of her car to help and in those days it wasn’t compulsory for the wearing of seat belts so none of us ever did as we were constantly in and out of these motors all day long, the impact and not wearing any sort of restraint allowed me to slip off the seat and end up in a heap out of sight on the car floor, (totally unharmed), the impact had obviously damaged the front end of the car which was only flimsy being glass fibre but it damaged to door I was trying to open to get out of the car and up from the floor and kicked it open just as this frantic lady reached it with a look of fear upon her face as she thought to make matters worse she had collided with a disabled person and imagined all sort of horrors regarding injury to me. Imagine her relief when I emerged from the damaged vehicle, stood up with a puzzled look on my face and walked over to her as she was panicking and asking if I was ok, she quickly settled down when she realised no one was hurt and apologised saying she saw me but it never registered in her mind as she was tired having just finished her work which were long shift hours and agreed upon my request to supply me with a written statement clearing me of all blame for insurance purposes after getting the approval of her personal solicitor much to my relief, I contacted Roy Halls explaining what had taken place and after satisfying himself I was not injured in any way, sent a recovery trailer out to collect the damaged car for repair back at the factory, no more was heard of the incident by me.

This second incident for me personally was even funnier still but first I must explain the situation and circumstances beforehand. Within close proximity to where our test and rectification departments was housed at the other end of the same main factory building was another department which was a section used by the men from the ministry and their job was to do a Pre Delivery Inspection on each car prior to accepting them after we had undertaken the appropriate corrections on each vehicle to their satisfaction (a little like an Mot if you prefer to view it). The chap who was considered to be in charge was the main person permanently stationed at the factory and who only got extra assistance from other ministry testers when the loading got too much for one man, he was a pompous individual full of authoritism, hated being there and did his best to let everyone be aware of this fact by his actions and mood swings each day as he went about his work inspecting these cars and woe betide anyone if he had a family disagreement at home prior to arriving at work, we usually bore the brunt of his anger one way and another and was well despised by many of us because of this fact. One day upon returning from a test run in an invacar came over the brow of church hill as usual at speed, now in case the reader of this is not familiar with the road or area I will endeavour to explain, the hill is steep and has opposing corners top and bottom and is around a hundred or more yards in total from top to bottom. As I reached the brow there was a slight hump in the road that as you passed over it the car became airborne for a split second and had a tendency to jolt the car slightly over to the right but when you got used to this anomaly you simply re-corrected your line of travel bringing the car back on track to continue safely down the hill at speed. Now this particular day just as it always did this of all things climbing the hill coming toward me on the opposite side was a police car containing three policemen one of which was a sergeant. The look of fear and surprise was apparent upon the drivers face as he thought an accident was imminent and immediately slammed on his brakes whilst pulling into the kerb, this was observed by me as I quickly glanced in my interior mirror and saw the bright illumination of his brake lights. Thinking they may turn around and chase me I tore down the hill at full throttle as usual and reached the safety of the factory where I raced down the side road of the main factory onto some waste ground at the rear where we stored many cars either awaiting delivery or pre inspection and screeched to a halt, leapt out and proceeded to go through the engine tuning motions burying my face inside the engine compartment at the rear of the car. Carefully glancing over my shoulder as I was doing this, sure enough three angry bobbies appeared glancing all around somewhat confused as there were a few of us fellows around and a whole lot of blue cars all looking much the same as one another. A few yards away at the end of the concrete side road I had just roared down sat this very ministry man whom we despised calmly sitting inside writing out his usual trivia complaint sheet totally unaware of anything else going on around him, and what I didn’t know was the fact that he had arrived from the same test run just minutes before me and I in fact had just shot past him in the last few seconds. A puzzled bobby walked straight up to him as he was the only one sitting in a car and tapped on his window asking him if it was he who had just come down the hill, to which with an equally puzzled look upon his face agreed he had indeed just come down the hill moments previous and couldn’t remember seeing any sort of police car pass him in the opposite direction let alone frighten the life out of them by his aggressive driving (even though as with the rest of us he drove just as fast). Hearing them reading him the riot act and getting the rollocking I should have received, I could not stop laughing to myself upon realizing what was taking place muttering to myself, “well, well, well, that mix up couldn’t have happened to a nicer fellow” and went home that evening thoroughly chuffed, feeling, right or wrong, justice had been served at least for that day anyway, which for me anyway was one of the most fulfilling days of many a year since whilst working there, LOL!!.

During my time working there I heard many hilarious escapades endured by Derry Preston Cobb told to me by one or two close aides and helpers of his that took place some prior to my joining the company and one or two during my time there. The poor chap was born so severely handicapped and restricted he seemed to have little fear of his own life and often urged anyone taking him out in a car to go hell for leather come what may, the faster the better as far as he was concerned almost like a death wish. Prior to taking delivery of his latest model of carriage he went everywhere in his open top chariot that he constantly had all the latest improvements fitted to the engine as they came available to give him maximum speed and power as he drove at breakneck speed everywhere in it. The rear of the vehicle had a special drop down tailgate that allowed him to be pushed straight in wheelchair and all and be secured in before leaving the company to head for home or wherever he happened to be heading at the time, and upon arrival at the firm he would sit patiently outside having given the usual toot on the horn to announce his arrival indicating for someone to unclip and wheel him into his office in his wheelchair. One evening as the story goes he left the factory as normal but as he climbed the steep church hill around a half mile or so distant the person that evening that put him into the vehicle had accidentally forgotten to secure him into the car, the steering on this machine was by a single tiller bar with everything done by him using one hand. As he began to climb the hill the tailgate automatically dropped down and his wheelchair began to depart from the vehicle, struggling to hold on to the tiller bar he finally had to release his grip and promptly rolled back down the hill ending up in a ditch by the roadside. Worried folk who had witnessed this catastrophe rushed over to help him fearing terrible injuries sustained by him during this ordeal were shocked and surprised to discover him lying close to his wheelchair in fits of laughter declaring “the silly sod forgot to clip me in with the safety locks” such was the humour of this remarkable individual.

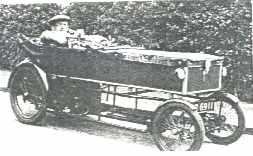

[DERRY PRESTON COBB HAS HIS OPEN TOP PURPOSE BUILT INVALID CARRIAGE BUILT PRIOR TO HIS FINAL MODEL 70 WHICH WAS SPECIALLY ADAPTED WITH A RAISED ROOF TO ACCOMMODATE HIM, COMPLETE WITH HIS PERSONAL WHEELCHAIR, AMID OTHER MODIFICATIONS REQUESTED BY HIM TO GAIN MORE POWER].

Another time I was told of an episode whereby he was given a treat trip one weekend on a yatch owned by one of the directors or office workers who was also one of his close aides and for safety sake he was strapped to the mast somehow to prevent him from falling overboard, but then an unexpected calamity befell the boat and crew causing the boat to capsize with Derry of course still strapped to the mast. Somehow, the panicking crew struggled and managed to right the boat, fearing Derry had by this time drowned, only to find him still intact spitting sea water out of his mouth, gasping for breath and once again laughing his head off jokingly declaring they were hell bent on drowning him, it seemed as if very little in the way of a dangerous situation worried this remarkable person with such a severe disability. Production remained fairly constant throughout the years regarding the Invacar, with a regular six a day rolling of the static assembly line in little more than a hour it took to complete a vehicle from scratch, and invariably the assembly guys would complete their days work in early to mid afternoon with a few of them preparing their sub assembly small parts in preparation for the following days work to avoid any mad rushes and ensuring a smooth flow of their particular section. Naturally the management were somewhat opposed to the idea of the workforce not grafting right up to the agreed and of the working day bell (so to speak) and occasionally tried to press the workers to increase the output by another one car per day. This was met with resistance by the majority of the fellows especially as no forthcoming rewards to attempt this was on the table, having felt they had given their all merely to produce the cars in such a short space of time anyway, and besides which it would be a pointless exercise simply because if this was done they would outstrip their allocated weekly supplies and have to stop work as a result of this anyway. Not sure how true this is but it was once said that in the design variation available there were 56 different styles of build to accommodate every type of disability that may be encountered for the day and jokingly it was coined one more variation and it could have been forever known as the Heinz 57 variety, LOL!!.

Being able bodied the majority of us testers much preferred the standard handlebar version as we could control the steering much more precisely much (like a motorcycle) and found aside of any high wind these cars to be extremely safe and stable otherwise considering they had only a three wheel configuration. Indeed, as the controversy raged I accompanied John L Ralling where he conducted wind tests at southend airport on one invacar I drove using a huge four engine turbo prop transport plane that was parked on the concrete at right angles facing away from the section where we were conducting the test and for a few minutes ran at full power to supply sufficient turbulence as to try to re-create driving conditions in an abnormally high gale force wind as I drove up and down past its wake so John could see first hand at least one of the problems these machines suffered in such conditions. I think it was realised that very little could be done to combat this problem or ease the severity suffered by these vehicles without a complete re-design of the front of the car adding the necessary extra weight and stability required to achieve this aim. Another time a team of us testers took a number of cars back to the airport amid all the controversy which was quickly picked up be the local press looking for conformation of these claims being made regarding the stability and safety factor of these vehicles amongst other claims amongst the disabled fraternity, and on a huge open concrete section at the airport we were all given carte blanch to drive these cars to their limits in any way we so wished. This we all did and with a lot of lunacy we drove around madly, often putting the cars on two wheels to the extreme but as soon as the handlebars were released due to the simple steering arrangement the tiller went immediately to the straight ahead position allowing the vehicles to simply be returned safely back down, in fact personally, I think it would need to be a real severe case to be able to turn one completely over under normal circumstances one exception to this fact may be the steering wheel versions which by design comparison did not react as rapidly and positive as the handlebar and tiller configuration.

One time I was asked by John Ralling if I cared to accompany him in a trip by light airplane to another county regarding further tests upon these controversial claims that were being made, cannot remember if it was The MIRA testing facility or some other premises and a test car would be delivered by road to us when we reached our destination. I declined the offer to fly as I have a fear of flying and the decision was made for me to accompany one of our lorry delivery drivers taking motors close to the area and dropping me off within a few miles of the destination of which I would continue by driving the car on the final stretch myself which I did. On the return journey I drove the car back as usual on trade plates and travelled in part along a stretch of motorway which by this time invalid cars were banned from, I was exempt from this fact by the sheer use of the trade plates being a tester as was proven when a motorway police patrol car overtook me and upon observing the trade plates ignored me and continued on their way. By the time I was halfway or more home the car was getting more and more run in and the speed was gradually increasing the further I went as it got worn in and one fellow I was behind at one stage nervously kept glancing in his rear view mirror not believing what he was witnessing with me aggressively in his boot trying to overtake. Carefully testing my power reserves available I reached a section of road where it was safe to overtake and squeezed past this car in excess of 70 mph on a downhill stretch, as I passed I glanced across to him with a huge grin on my face to see a look of disbelief upon his face and with him shaking his head and doing circular motions with his finger around his right ear signalling that I must be some sort of madman to try such a thing in an invalid car of all things which was up till then no doubt unheard of as a common occurrence, I laughed all the rest of the way home with the sight of his face stuck firmly in my memory.

I was often stopped by the police whose officers thought they knew the laws governing the speed restrictions laid down for invalid carriages and tried numerous times to read me the riot act regarding excessive speed until I pointed out to them the official windscreen sticker that was put at the bottom middle of every new car that clearly stated not to exceed the speed of 55mph until suitably run in, upon reading this they invariably grunted that they would need to look into this further as by this time doubts were raised in their minds, but none of them ever pursued this threat for one reason or another. Toward the demise of the company a local engineering company named Elmsleigh Engineering that had for years specialised in the overhaul and repair of engines, was in financial difficulty and subsequently up for sale, this concern was subsequently purchased by our company, (don’t know the original purpose behind this move). Prior to the final months of the ministry’s cancellation of invacar orders I believe our company as a whole was put up for offer and this was taken up by a fellow by the name of P.H.Simpson a fellow who lived but a half mile or so from the factory and had for a time worked under me in the test and rectification department. He had previously gained experience of managerial running of small concerns and decided this was an opportunity not to be missed, and a deal was struck whereby part of the main factory would be cordoned off, Elmsleigh Engineering would be moved into the rented area together with a few of its original staff to run the relevant machinery of which they were familiar with, and the rest of the factory either let or sold to alternative tenants.

Prior to our most of our redundancies many including myself were offered a continuing position with another section that was being organised which was to create a repair base for existing vehicles that were considered to be around for many more years to come until one by one no longer manufactured parts that may be required would be sought by the cannibalisation of other existing cars that had reached their sell by date through one reason or another hence by this method keeping as many cars in a roadworthy condition until the whole design was eventually scrapped altogether and alternative vehicles selected to replace them for the future. Not certain if this enterprise would be affiliated within the company takeover as a whole or if it became a separate unit in its own right. I declined the offer, one, because we were offered the chance of reclaiming all the weekly payment we had made previously to a pension plan to allow us some sort of buffer of finances should we prefer to have or otherwise to help us financially if we were not fortunate to gain other employment quickly as no such thing as redundancy pay was in place at this company at that time. The company however did try to secure many job offers for us by contacting the local surrounding companies on our behalves. The second reason was because I personally did not always see eye to eye with the fellow I had worked alongside and more often than not we had a clash of personalities, resulting in the thought of having him as my employer did not appeal to me at all so finally took the decision to depart from the company completely. I believe however this man brought his family in as part of the workforce mainly in a managerial capacity gradually handing over the running of this remaining part of the original company to his offspring one of which I think may still run the company today with a workforce of some 20+ employees and still using the sectioned off part of the original Greeves/Invacar factory. It is said all good things must come to an end and for me it certainly was a sad day when i terminated my employment finally after 10 odd happy and contented years working there as it was akin to working as one big happy family for the best part and aside of the thought of working for the fellow who eventually bought out the remains of the company coupled with the thought of getting a lump sum from the returning premiums I had been paying into the company pension funds was too much to turn down, can’t say if I may have thought twice should the potential purchaser may have been someone else and stayed on."

Virtualgaz: Dec 2009 Dave 'Hedgehog' Price - where are you? (email link is no good)

Peter Wonnacott: "Hi Gaz, I read with interest the article by Roger Saunders regarding Roy Halls and had a grin from ear to ear when noting his many remarks as to the many escapades that took place over a period of time during his employment at the factory. I worked at the factory for a period of some ten years in total, the first quarter of that time was as an engine assembler in the Greeves Motorcycle section and after a short break, resumed my employment to work in the Test & Rectification Department of the Invacar section.I worked through the ranks until finally becoming Chargehand until the closure of the factory.

Throughout my period of employment, Roy Halls was the main person many of us dealt directly with and I found him, like many others, to be a thoroughly pleasant fellow to work under. The workforce only consisted of a couple of hundred at most but it was like one big happy family as everyone knew everybody and it was always a joy to look forward to go there to work each day. Being one of the main Invacar testers, I must have been possibly one of the few to actually beat Derry Preston Cobb in an out-and-out race! One day he challenged me to a duel after having some improvements done to the braking system on his uniquely modified Invacar which had the new 600cc Steyr Puch Engine fitted (an uprated version of the standard 500cc type). Derry's Invacar was the only version that had a modified raised roof to accommodate him together with his wheelchair, which had to be clamped in for security. Accepting the challenge I selected a car from stock that had only just been roughly run in that day around our standard test run circuit (which was simply a few miles distance). To help matters I manually slackened all the brake drum adjustments off to ensure no friction from the new shoes thereby giving me optimum speed without any drag from then. We set off and Derry was ahead of me. I managed to squeeze past him as we raced down the 127 Arterial Road (but not easily I might add) as I felt it was a challenge race after all! I have to say that Derry, for all his disability, drove and handled that carriage with all the skill of an able-bodied person and had complete control throughout, however I don't think he was impressed at having lost the race - even though he congratulated me upon our return to the factory. Good fun and a laugh was enjoyed by one and all.

Sooner or later, working at the factory meant working outside in all weathers. When accommodated inside, it gave many of us protection from the elements; not least including the section occupied by the men from the Ministry who pre-inspected the vehicles prior to accepting them for final delivery. One of these fellows was disliked immensely for his pickiness and mood swings and how he would take it out on others, giving the impression he didn't want to be there in the first place. One day whilst returning from a road test in one of the Invacars, I approached the brow of the hill which Roy has mentioned here. It was a steep gradient with right-angled curves top and bottom - in a sort of slight 'Z' configuration. As i reached the peak at full throttle I hit a raised bump in the road which put me airborne for a split second and at the same time launched the whole car over to the right by a foot or two... straight into the path of an approaching Police Car which was climbing the hill containing three policemen including a sergeant. Quickly correcting the line of travel to the original as the Police Car jammed on its brakes in fear of a possible collision, I carried on down the hill regardless, noting in my rear view mirror the bright illumination of the Police Car's stop lights. Some quarter to a half mile further down the hill I reached the safety of the factory and blasted my way at full speed down the side of the factory to the open ground at the rear where lay the Test & Rectification department. I promptly leapt out to perform minor adjustments to the engine as was usual prior to passing the finished article over to the Ministy for further acceptance. As expected, with my head buried inside the engine compartment, the Police arrived looking for a blue Invacar (of which there were invariably quite a few) with driver in order to deliver a reprimand for dangerous driving on a public road. Turning my head around I noted that the very Ministry man whom was despised had (minutes earlier) arrived ahead of me and was sat unsuspectingly in an Invacar he had just himself tested, writing his usual reports and totally unaware of what had just taken place. He was the first person the Police approached and now within earshot, I heard them ask him if he had just travelled down the hill? Somewhat confused he replied that yes indeed he had - and then proceeded to get a severe ticking-off by the nice Policeman, promptly giving him a lesson in dangerous driving, which he accepted with a puzzled look upon his face... not remembering having nearly collided with a police car during his test run. Struggling to retain my composure upon hearing this guy getting a dressing down on my behalf really made my day with me muttering under my breath to myself "that couldn't have happened to a nicer fellow" and went home that evening feeling some sort of justice had been delivered, right or wrong, to a person that was normally on the side of dishing often trivial unfair and nasty authority out to others - a bit like Scrooge in A Christmas Carol (Bah Humbug, LOL!!).

Hoping this story may give others who remember those days at the factory more of the laughs many of us used to enjoy during our happy days there" Peter G Wonnacott [peterwonnacott@googlemail.com] 2009

![]() Richard:

Hi, I was reading your web site regarding the Invacar Model 70. I have one

of these, on the road. I had a problem with a snapped belt. I managed to

get a new belt and while fitting it I checked the ratio of the gear box in

forward and reverse. I just wanted to let you know that, contrary to

popular belief, reverse gear has a lower ratio than forward. In reverse

the box gives 1 to 1. in forward it has a 1 to 1.25 increase on the output

shaft. Still makes them pretty quick in reverse !!

Richard:

Hi, I was reading your web site regarding the Invacar Model 70. I have one

of these, on the road. I had a problem with a snapped belt. I managed to

get a new belt and while fitting it I checked the ratio of the gear box in

forward and reverse. I just wanted to let you know that, contrary to

popular belief, reverse gear has a lower ratio than forward. In reverse

the box gives 1 to 1. in forward it has a 1 to 1.25 increase on the output

shaft. Still makes them pretty quick in reverse !!

Best Regards, Richard (2009)

Roger Saunders: "Hi Gaz, I worked (until the end of 2008) in a Comprehensive school in Wickford, Essex. When the Thundersley factory closed Roy Halls, Works Manager at Greeves Invacar, was out of a job. With his engineering qualifications he applied for a job as a Metalwork teacher and worked out his time until retirement with Unqualified Teacher status. "Unqualified" was a real mis-nomer. He bought a wealth of skill and experience. Jigs were introduced and metalwork lessons were production lines in minature. What I remember most, and what moves me to write to you, were his stories of the old Greeves Invacar Works. Derry Preston Cobb certainly had a powerful engine in his Invacar. Every time a new improvement came out on the Greeves motorcycle engine (built in the same factory) he insisted on having it on his machine.The final engine was the Greeves version of the Villiers Starmaker racing engine, which was far too fast for the chassis. Employees were instructed NEVER to overtake Derry on the A127 on the way to and from work. He would invariably race them and, with his limited mobiltiy, accidents were common. Actually, he seldom hurt himself as he just landed like a rag doll. His disabiltity made people think he was really badly injured. Derry couldn't bend his body at the hips, so had a special car where the wheelchair was loaded from the rear. When he arrived for work he hooted and they came out and unloaded him. IMMSMW, the picture above "After some dubious 2 seated versions in the early 50's..."may well be of Derry in one of the early Invacars. According to Roy, they built the chassis in a jig, but, no matter which sequence was used in the welding process, it came out about half-an-inch (12mm) different from one side to the other. After many trials they just made the suspension mounting longer on one side to compensate! There were many and varied versions of the control system; foot and hand brakes, R/H and L/H throttles (operated by hand, foot, knee, elbow etc.), wheel and bar steering (with bars central or pivoting Left or Right) and all sorts of individual modifications which depended on the disability of the driver. Roy recalled that it was a nightmare if you were asked to drive one. You got in and took several minutes to work it all out. He thought the Works Testers were incredible. They would use the very steep Thundersley Church Hill, just up the road from the works, to check performance, brakes and handling. Seeing them descend at indecent speeds was scary for the onlookers, let alone the Testers. Early Invacar versions were much harder to drive than the automatic later models. Roy said that he was amazed at the skill of some considerably disabled drivers, who drove with great confidence. Others "should never have been allowed out on the road.." Trusting that this may be of interest to yourself, Roger Saunders". (2009)

.Dan Vitaletti: "Here's a scan of a sales brochure for a Mark 12C Invacar to post on your great website.Thanks Dan Vitaletti Colorado USA".(2005)

Daniel Rodd: "My friend Stuart Cyphus runs the 'Invaliud Carriage Register', which is a special register/page for Invacars and owners in the Register of Unusual Microcars magazine. He would be very grateful to hear from anyone who owns a surviving invalid carriage, or anyone who has any recollections, photos etc. on them. To join the Register of unusual microcars write to: Jean Hammond, School House Farm, Boarden Lane, Hawkenbury, Staplehurst, Kent, TN12 OEB. As a member you'll get a quarterly full colour magazine dedicated to the more unusual microcars, including seperate pages for different makes in the registers which have their own registrars, including the Invalid Carriage register. Stuart has on his register a grand total of 128 surviving road going invalid carriages (from the 1930's onwards). So the government didnt get them all!! Many were donated to museums, owned privately (ie were never government owned in the first place, as up till the mid 60's you could buy invacars yourself) were not on DSS books, or were"obtained" by other means, and there are many more out there, I know personally of someone with 10 in his garden, which have been there 30 odd years. Basically this means that there are surviving invacars out there and long may there be, but if you could put the above info on your invacar site that would be great, and a plea for anyone who owns or knows of any invas to contact Stuart. All the best, Daniel Rodd (2005). His Contact details are:"

The Invalid Carriage Register, Stuart Cyphus,

6, Mirfield Road, Witney, Oxfordshire, OX28 5BA

Tel 01993 709452.

Dan Vitaletti: "I recently restored and sold my '63 Invacar to a Disability Museum in New York (only museum of its kind in the USA). I can provide a short story and photos if you want for the website. Thanks Dan Vitaletti Colorado USA".(2005)[great Dan, looking forward to it]...

Ian Bingle:"Here's a question for you! There was a recording about the Thundersley Invacar. TRUE!! I remember it well, but no-one else seems to! (and I am NOT going round the bend!) I have tried to trace it without success! Have you heard of it? Best wishes, Ian (2004)

[Well, we didn't, but we do now, thanks Ian !...3mb of Collapsed Lung's finest moment...]"Collapsed Lung - Thundersley Invacar".

Ian Bingle: "I have a "street-legal" Tippen Delta electric. I have owned it for about 10 years and I think it may have been part of the manufacturer's batch allocated to the British Legion. My Tippen was manufactured in 1974 and the chassis plate states this. 'Manufactured by Frank Tippen & Sons 1974' plus serial number etc. The problem with all invalid vehicles (and indeed with London Transport buses) is that the year shown may not be the original year as these vehicles frequently get refurbished and re-registered with different bodies etc. This would certainly be true of the later Thundersleys. I believe, however, that my Tippen was genuinely made in '74. Another weird thing is that the fibreglass body appears to be self-coloured in the Ministry blue. And yet it has been re-sprayed a very slightly different shade, which is now peeling off to reveal the original colour! Ian (2004)

John Benson: "Hey there Virtualgaz, You set a hard task (of tracking down a rogue IC he saw in June 2004)... but today I saw our target... after a wild goose chase around Hove (UK) today (spotted the car, but didn't have the camera!) dashed home and went back to Sainsbury's... possibly the first Invacar being tailed too? Anyhow here are some photos, it's taxed too till next year so will prob be with us for a while... Regards John" (July 2004) (brought to you by www.crosscurve.com -making your ideas into reality)... PIC#1 PIC#2

Ian Campbell: Hi, back in the 70's I worked for a company "Hatherlys" in Footscray, Kent (UK) who had a Ministry contract to service invalid carriages. In the trade they were known as "Cruds". Recovery of broken-down carriages were made with a van towing a two wheeled ambulance, you just picked up the front and dropped wheel into the channel on the ambulance. It was not unusual to be hooted at and told "eer mate it's fallen over". As mechanic's testing carriages, we all had to pass a test - a man from the Ministry came, we drove round the pumps on the forecourt and that was it! We had one client who had an AC spinal special (like a stretched limo), he drove it from a prone position. It had a red flashing light fitted incase he got into difficulties. There were still a few electric open (Stanley?) carts around with the tiller steering. Party trick by us naughty lads was to reverse back couple of feet then slam it into full forward. If nothing broke the resulting wheelie was most impressive!!! Best Regards, Ian Campbell (2004)

Dave Price: " I heard there was to be a reunion with all the surviving Thundersley workers this year. Does anyone know anything about it?" Dave Price, ex Thundersley lorry-driver / packer. (2003)

Graham Walker: "HI THERE,I USED TO OWN A MODERN AC INVACAR,TO WHICH I REMOVED THE ROOF,ADDED WIDE ALLOY MINI ALLOYS WITH LOW PROFILE TYRES, ADDED 2 HUGE SPOTLAMPS, PAINTED IT BRIGHT RED, AND WAS EVEN SEEN ON BBC 'TOP GEAR', BEATING A MESSERSCHMITT TIGER IN A SIDE BY SIDE SLALOM RACE!! BELIEVE IT OR NOT I EVEN OUTCORNERED HIM, AND I HAVE THIS ON VIDEO....A GREAT CAR...CHEERS, GRAHAM"(2003).

Dave Price: "I drove the the lorry and trailer delivering Invacars and the Greeves motorcycles for fourteen years. Derry Preston-Cobb (MD) had his own special invalid car with a Greeves racing engine, side mounted. It was a very fast machine and we regulary had to go and rescue Derry when he turned it over trying to corner too fast. When he had to give up this machine, he gave me the engine to fit in my Bond mini-car. The Bond went so fast it frightened me, because the brakes were not efficient enough to stop it quickly. The lorry and trailer carried four cars, two on the truck and two on the trailer. To load the lorry, I had to drive up the lowered trailer tailboard and fast up a steeper ramp onto the back of the truck. The first car was easy enough, but with the second one, I had to brake sharply after speeding up the ramp, so as not to smash into the first one. I had some great times there and still have freinds I worked with". Dave Price (Hedgehog) (2003)

Q. Has there ever been an instance of a stolen Invacar? A. Yes, one of John Curley's customers has had hers stolen twice!

Q. Did you have to be 'disabled' to drive one? A. In the UK, it was the only lawful way.

Q. Is it true that you couldn't legally own an Invacar? A. All Invacars were Government/Council owned.

Q. Is 82mph the absolute maximum aerodynamic speed of an Invacar? A. No, 85mph is the reputed record!

Q. Do they really do 97 mpg? A. No, more like 35mpg in reality.

This is Ian in his 19?? Argson with Jon Heasman who runs a project called GAP (Garnet Access Project) which provides access to the countryside for disabled people. The Argson is being used by Jon to promote the project.

Possibly the only Greeves Invacar in North America? Dan Vitaletti of Colorado, collector of Greeves motorcycles, just had to have an Invacar - so when he saw this one for sale he paid a king's ransom and drove a 2,000 mile round trip to pick it up. It was the only Greeves Invacar imported by the Greeves Motorcycle west coast distributor, Nick Nicholson and is a 1963 Mk.12A (Ser. no. 81618) with a Villiers 11E (617D 2739) having covered a mere 2,219 miles.

This superb 1968 Tippen Delta belonging to A.M. of Massachusetts was originally taken to Nova Scotia by a war veteran. He would like to find out more about the number of surviving TD's and is currently searching for location of the serial number. Any thoughts anyone?

*Research carried out using a variety of information including Jon Curley's personal documentation and 'A Brief Pictorial History of the Invalid Tricycle' by Fred Nailer (1985).

| Automotive Creation - incl. Scimitar, Reliant and Robin | |